Acoustic inspection services

How our acoustic inspection service works

Acoustic inspections detect and accurately locate any type of electrical discharge, partial discharge and other early stage faults before they become visible, often up to 18 months in advance.

Using the latest technology from South Korea, we identify a wide range of issues, including cracked or damaged insulators not visible to the naked eye, as well as faults such as broken strands, corrosion, dead-end preform failures, splice and armour-rod failures, surface tracking, increased contact resistance, overheating and more. These detections are critical to preventing unexpected failures.

Our capabilities

Our acoustic inspection services are up to 10x faster than other methods, checking up to:

- 300 distribution poles/structures per day

- 30–50 transmission towers per day

- 2–4 substations per day

- 30 ground-mounted assets per day

Key features

- Accuracy – we can pinpoint locations of electrical discharge and defects up to 18 months before becoming visually evident

- Reliability – identifying and prioritising defects enables asset owners to manage condition-based risks

- SAIDI benefits – SAIDI reductions result in operational savings and improved public safety – including reducing customer outages and highlighting potential bush fire risks

- Innovation – state-of-the-art defect detection across electricity network assets

- Speed – our acoustic inspection services are 10x faster than traditional inspection services

- Rapid problem solving – quickly identifies root causes of intermittent faults on problematic network sections

Ground-based survey

Our drive-by inspections service (urban and rural) uses a state-of-the-art directional ultrasonic detector.

In areas with restricted vehicle access, inspection can be done on foot. We can also utilise a helicopter where site access is extremely difficult.

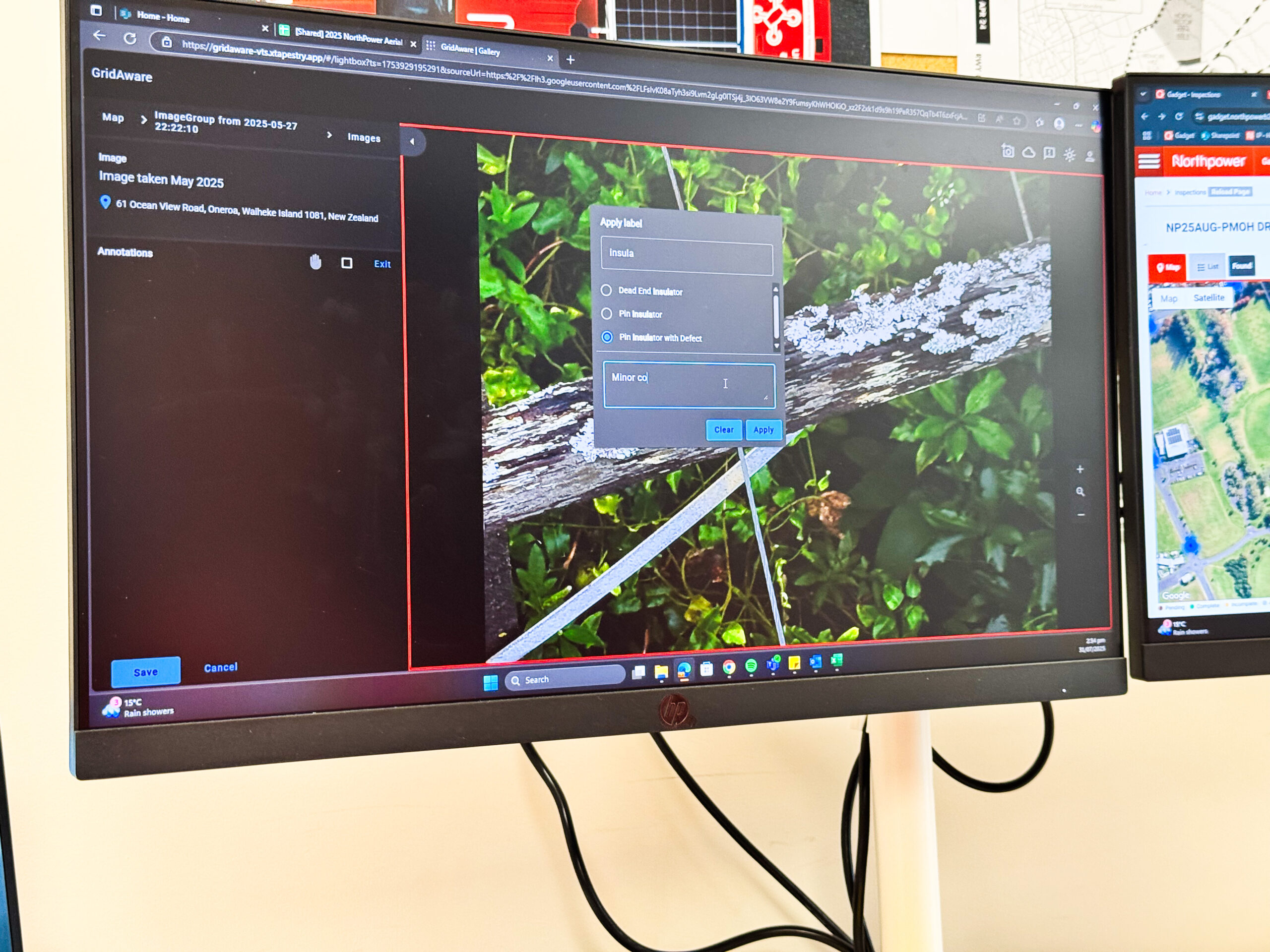

Identification of defects

Our specialist engineers are trained in the identification of ultrasonic defect signatures.

Once detected, triangulation techniques are used to pinpoint the defect location and high-resolution images and data are captured for analysis.

Diagnostics and reporting

Once field information is gathered, our experienced engineering team review the defect data determining the issues and offer potential solutions.

Forensic analysis and diagnosis allow for defect classification and prioritisation according to our customers’ network standards.