Acoustic specialists on Powerco network

Location: Hawkes Bay

Start date: 2018

Completion date: 2023

Project partners: Powerco

Identifying electrical equipment issues

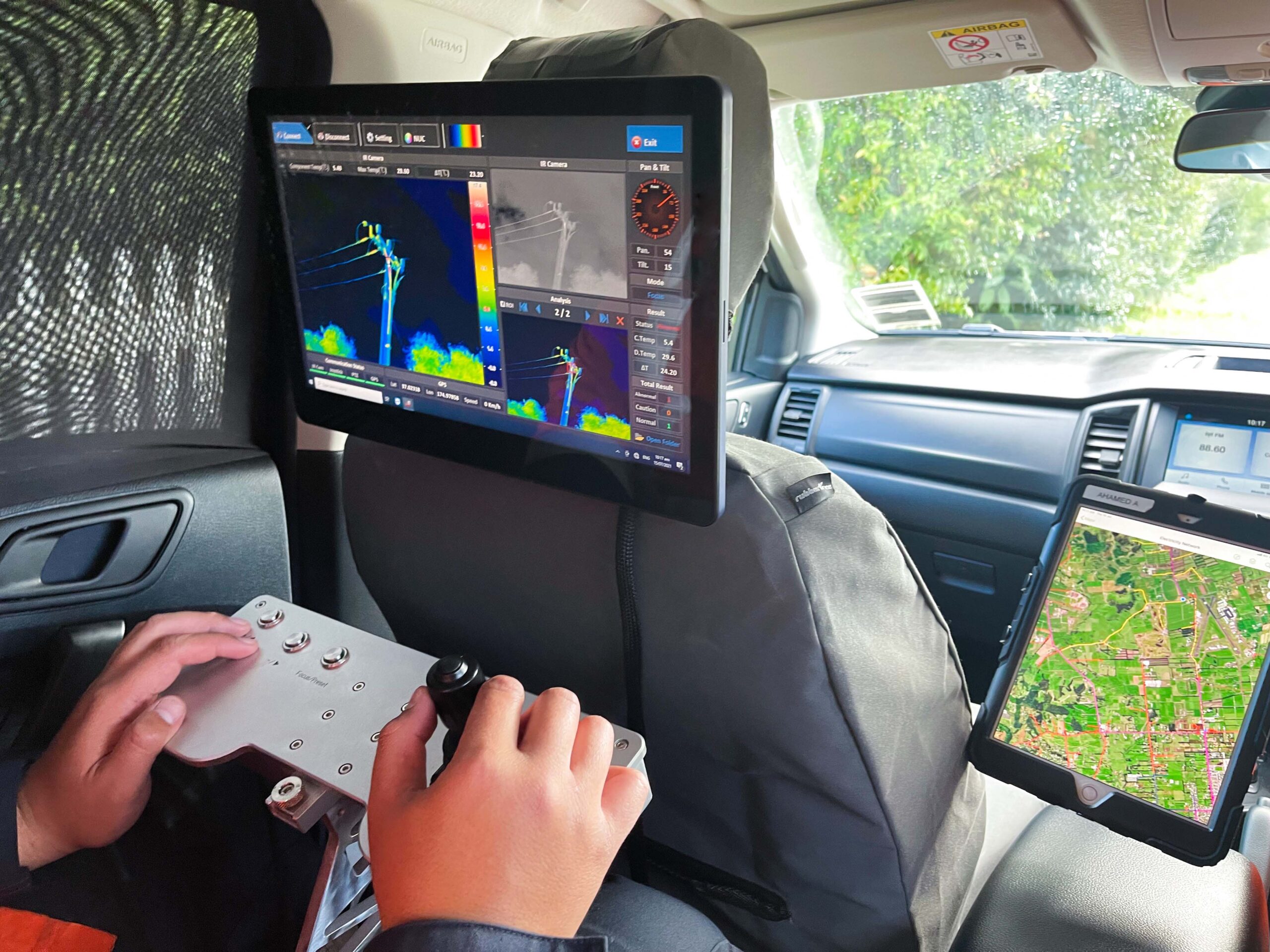

Northpower’s innovative acoustic inspection technology is revolutionising the way potential electrical equipment issues are identified and addressed. By utilising sound-based technology, our acoustics team is proactively detecting defects, contributing to a more reliable power supply, and enhancing community safety not just for our own networks but across other networks too.

Our acoustic inspections team utilise sound to accurately locate various electrical discharge and defects, including hairline cracks, corroded insulators, and other issues that may disrupt the power supply. This technology can identify these defects up to 18 months before they become visible to the human eye, providing an early warning system for potential equipment failures.

Our team has executed monthly acoustic inspections and two conductor programmes for Powerco over a five-year period. The monthly inspections targeted the worst-performing feeders across the entire Powerco network, addressing instances where traditional inspection methods failed to identify the root cause of poor performance. In addition, separate conductor inspection programs assessed the condition of the overhead fleet, enabling Powerco’s asset engineers to profile the network, forecast failures, and streamline maintenance efforts.

Through these inspection programmes, our team has inspected 66,000 poles/structures, detecting 1,493 defects, including 929 acoustic emitting defects. Notably, 26 priority 1 defects (critical/faulted equipment) and 334 priority 2 defects (requiring repair or replacement within three months) were identified. The data collected from the inspections provided valuable insights for Powerco’s asset engineers, enabling them to prioritise maintenance activities and enhance network reliability.

The implementation of acoustic inspections has led to significant benefits, including minimised unplanned outages, reduced SAIDI (System Average Interruption Duration Index) minutes, and operational savings. By proactively detecting defects and prioritising maintenance efforts, Northpower’s acoustic inspections contribute to improved public safety and community well-being.

Northpower’s acoustic inspections represent a proactive approach to maintaining a reliable power supply and enhancing community safety. By leveraging innovative sound-based technology, Northpower continues to lead the industry in identifying and addressing potential electrical equipment issues before they escalate, ultimately ensuring a more resilient and efficient power distribution network for all stakeholders.